Horsemuffin

When Gwen and I bought our current house, we inherited a letterpress, vintage approximately 1920, that the previous owners could not take with them when they moved to Spain. Gwen was interested in learning how to use it, but knowing how the best-laid plans of mice and men can go, we agreed that if she hadn’t done anything with it in nine months, we’d get rid of it.

Well, she did do something—a batch of coasters (using type, ink, and stock that was also left behind). Then she made some postcards. My sister, who received one of these postcards and has her own craft business, told Gwen “if you make more like these, I can sell them.”

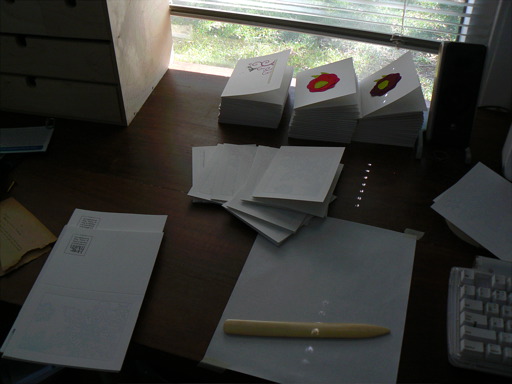

That got Gwen thinking. She designed a series of cards, got plates burned, bought paper and ink, and got to work. I watched.

It’s fascinating to contemplate letterpress printing. It’s a very fussy process. These days if we want a hard copy (a phrase that suggests how a paper instantiation of information is secondary to the platonic electronic form), we hit command-P and a few seconds later, a page (or many pages) pops out of the printer, perfectly rendered.

It’s a little different with letterpress printing. Assuming you bypass the laborious process of composing type and have a plate burned, you still need to affix the plate in your chase, estimate the correct amount of packing on your platen, estimate your gauge-pin positions, and print some “make-ready” to home in on the correct packing and pin positioning. Once you’re getting a uniform, square impression—a process that can easily take an hour—you can start printing. The packing (extra sheets of paper underneath your printed piece) determine how hard the plate’s impression is, and a single piece of tissue paper in the packing can make an obvious difference in print quality. And if you’re doing a two- or three-color job, you need to do all this repeatedly—and get your registration straight with the previous print passes. The whole process can go wrong in numerous ways, and our eyes are highly attuned to even subtle errors in printed matter. A piece that’s rotated so that a printed line that goes out of parallel with the edge of the card by just 1/30″ over a length of 5″ is an obvious reject.

And while we generally don’t think of printing as physically dangerous, with a letterpress, it can be. Because the equipment is, at root, a press. And it weighs about 1800 lb, running off a large flywheel carrying a lot of momentum. If your hand happens to get in the way when platen and plate are pressed together, you’re going to have a very flat hand.

In spite of the hard work, the finickiness, and the risk of grievous bodily harm, Gwen has produced a line of cards. They’re being sold at Book People, and will be sold on the East Austin Studio Tour and Cherrywood Art Fair.

Oh, and she has a website of course. Horsemuffin.